Moving a vessel in the twilight zone.

Breaking the deadlock

In previous articles, we have looked into the main issues of a yacht conversion and how to assess a donor vessel. (see links below)

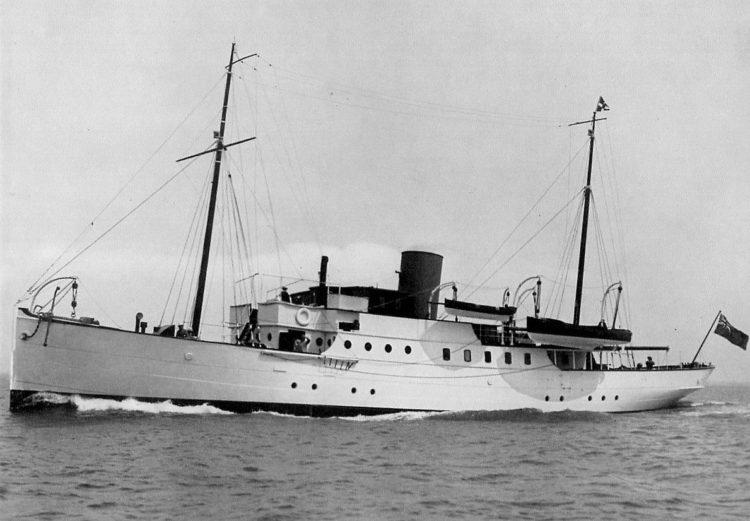

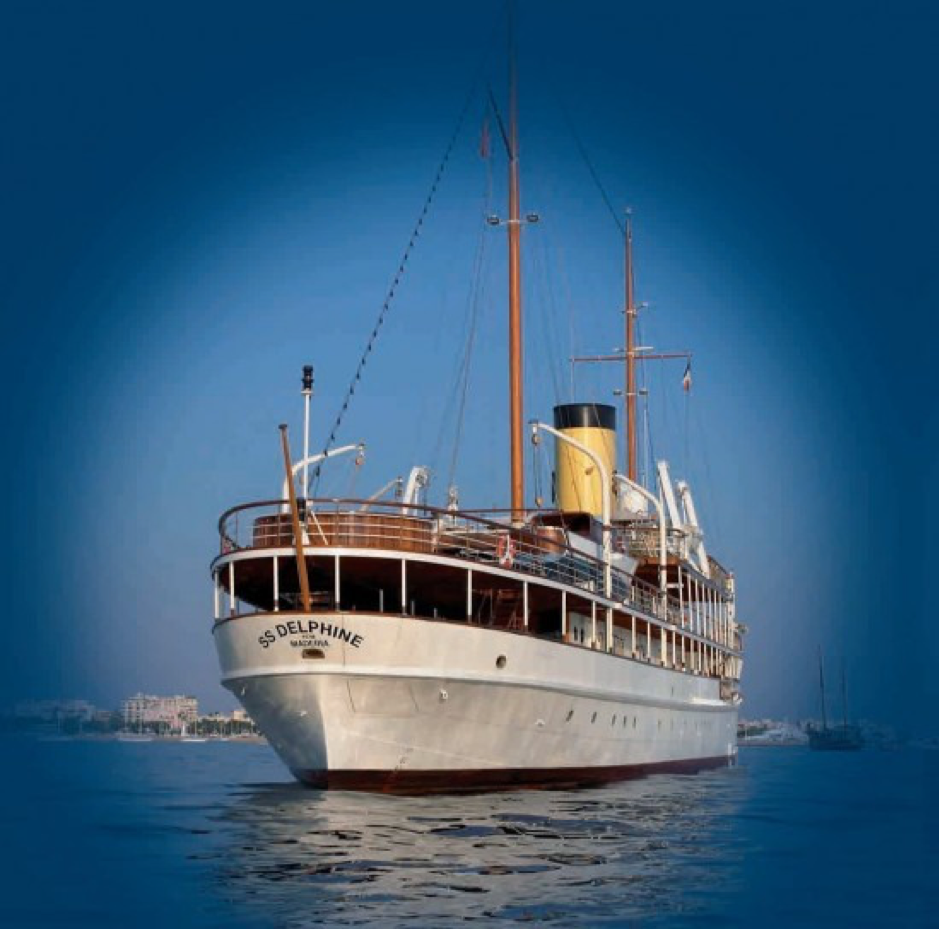

Now the vessel has been chosen and it needs to be moved to the appropriate shipyard or location for the start of the conversion. In many cases the vessel is still “in service” and has a flag and a valid class. It is probably more efficient to move the object as is under her current status.

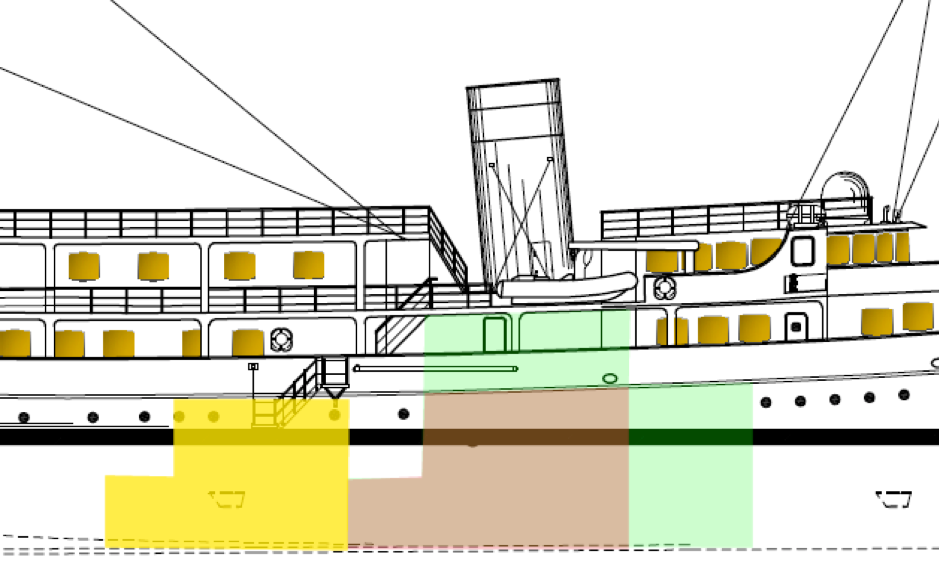

Questions arise when the chosen vessel has lost its class, flag or both, and maybe is not, or has never been, compliant with the status required after conversion. Some candidate objects have been long out of active service, may be former fishing boats, navy or government vessels, for which class and many statutory regulations do not apply. See also our article on the case of the local boat.

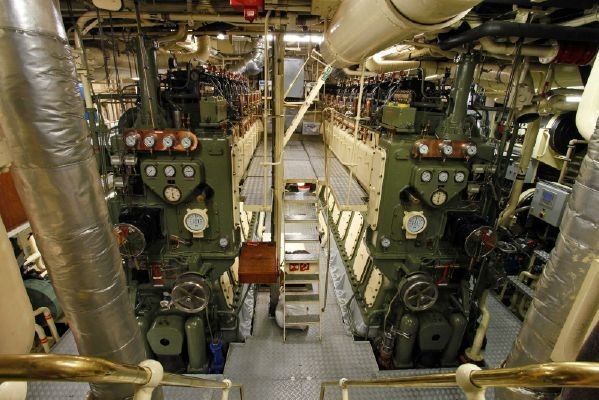

For high budget projects, the best way to move a vessel without title is probably towage or transport. A seaworthy vessel however can be summarily refitted and certified for the transit to the final yard. The list of works to be performed must be really carefully defined. In an ideal world, nothing should be added or modified that will not be kept for the final rebuild. The scope can also be wider than just necessary works: There can be an opportunity factor, in the place of purchase, to already prepare further rebuild elements, do engineering or steelwork, or purchase equipment that can be cheaper at the location than at the rebuild yard.

Of course, there is also the negotiation with class and flag to allow the vessel to sail on her own bottom. A change of flag and/or class may be necessary or useful, though generally not if the vessel is still registered.

Then there is the ultimate SOLAS weapon, regulation 4: the “authorization of departure”. This rule allows a flag to give permission for a ship to perform one single relocation trip to a shipyard without class or certificates other than a scope of inspection that the flag defines. Some flags are more flexible than others for this exercise.

Links to previous posts on conversions

conversions-and-refits

assessment-of-a-ship-for-conversion